3D Printing, CNC & Lasercutting

3d printing

3d printing for prototyping, product design and model making for architecture. First, the subject is 3d modelled, then opened in 3d printing software printing settings are optimized for desired results and lastly it is printed. Post-print processing included removal of stabilising extra material and sometimes sanding for desired finish.

3d printed ring prior to post-processing "clean-up"

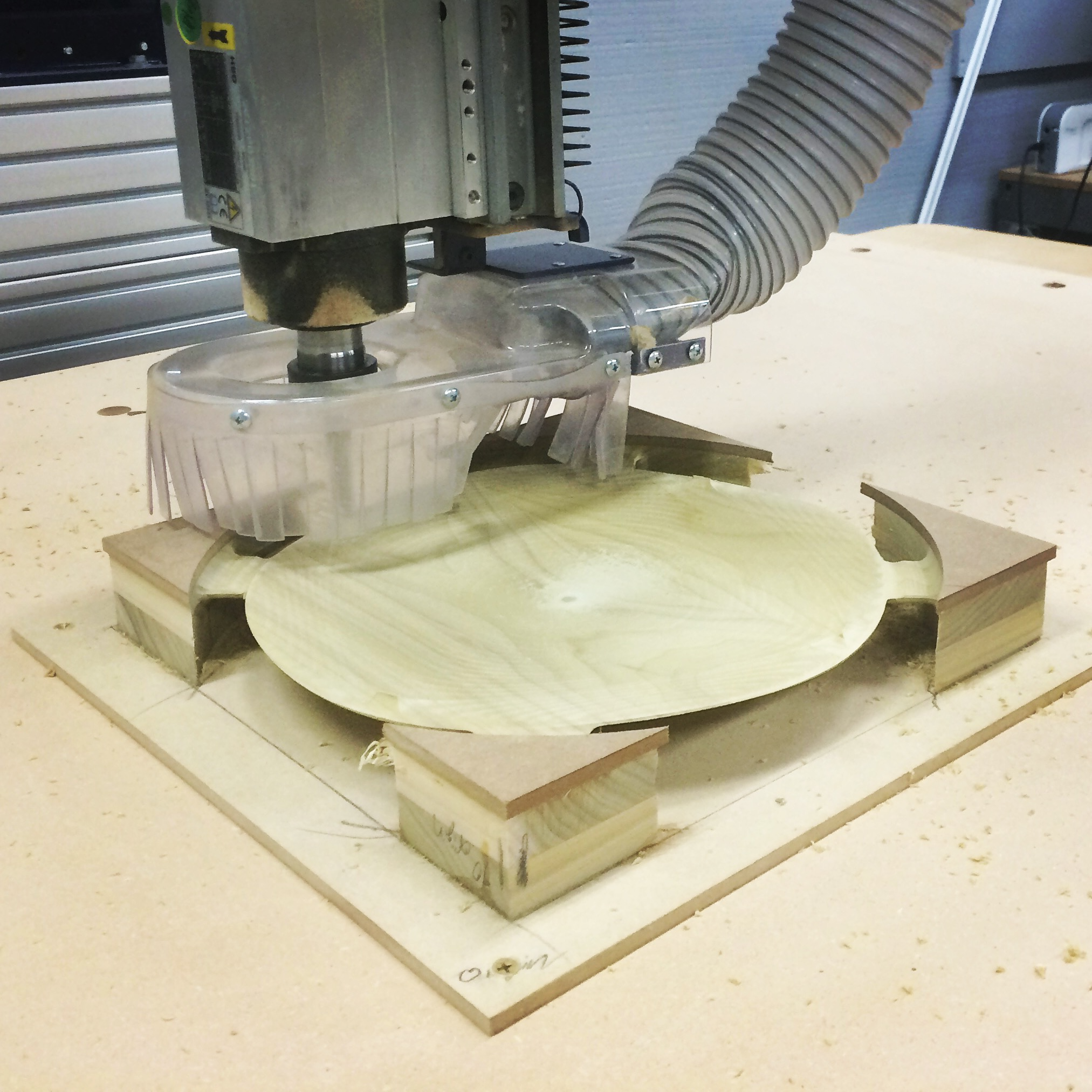

5 axis & 3 axis CNC Milling

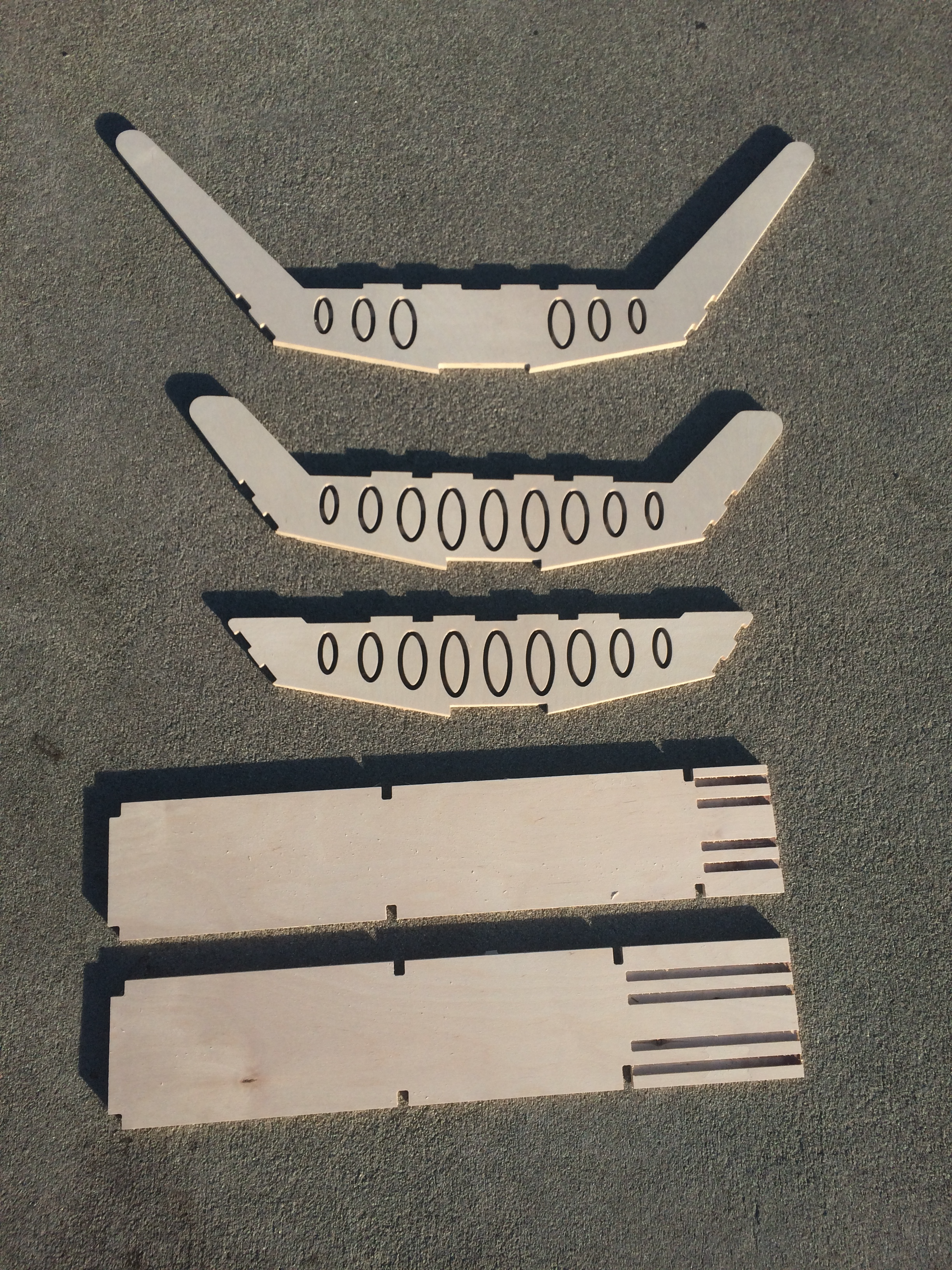

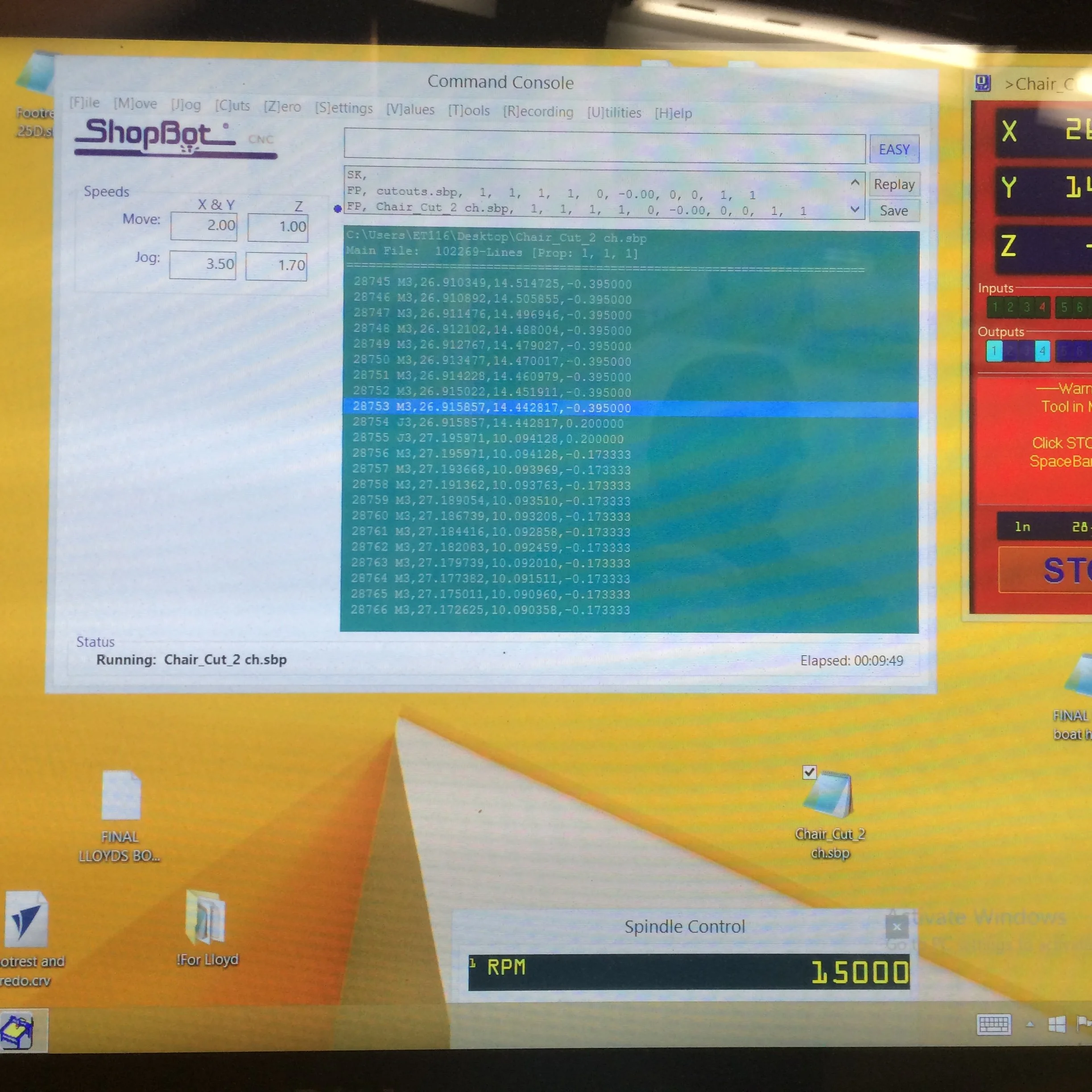

CNC projects are first 2D/3D modeled/designed. They are optimized for CNC milling with CAM software to develop efficient toolpaths with respect to material properties, finish, and efficiency. Then CNC machining requires analysis/selection of toolbit with respect to project specific parameters and desired design results. After safely mounting material, the project is monitored from start to finish. The final product is brushed and sanded if needed.

5 axis CNC Milling pinewood self-laminated block

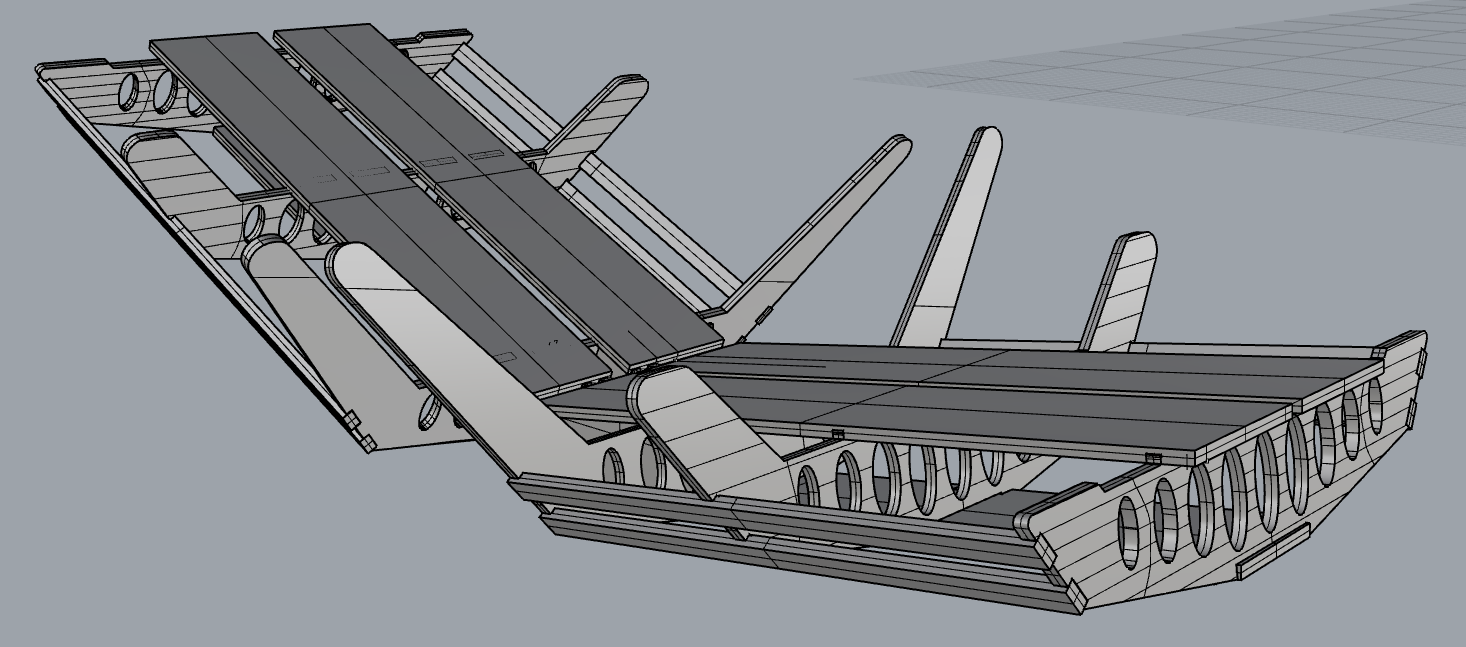

Wheelchair design for CNC fabrication

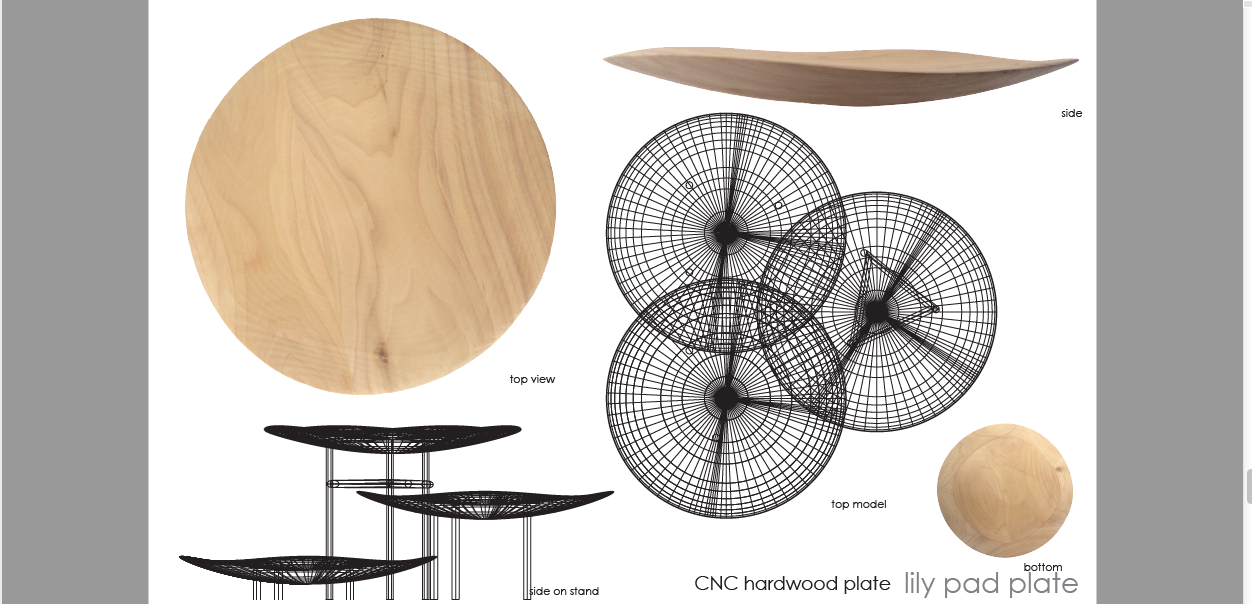

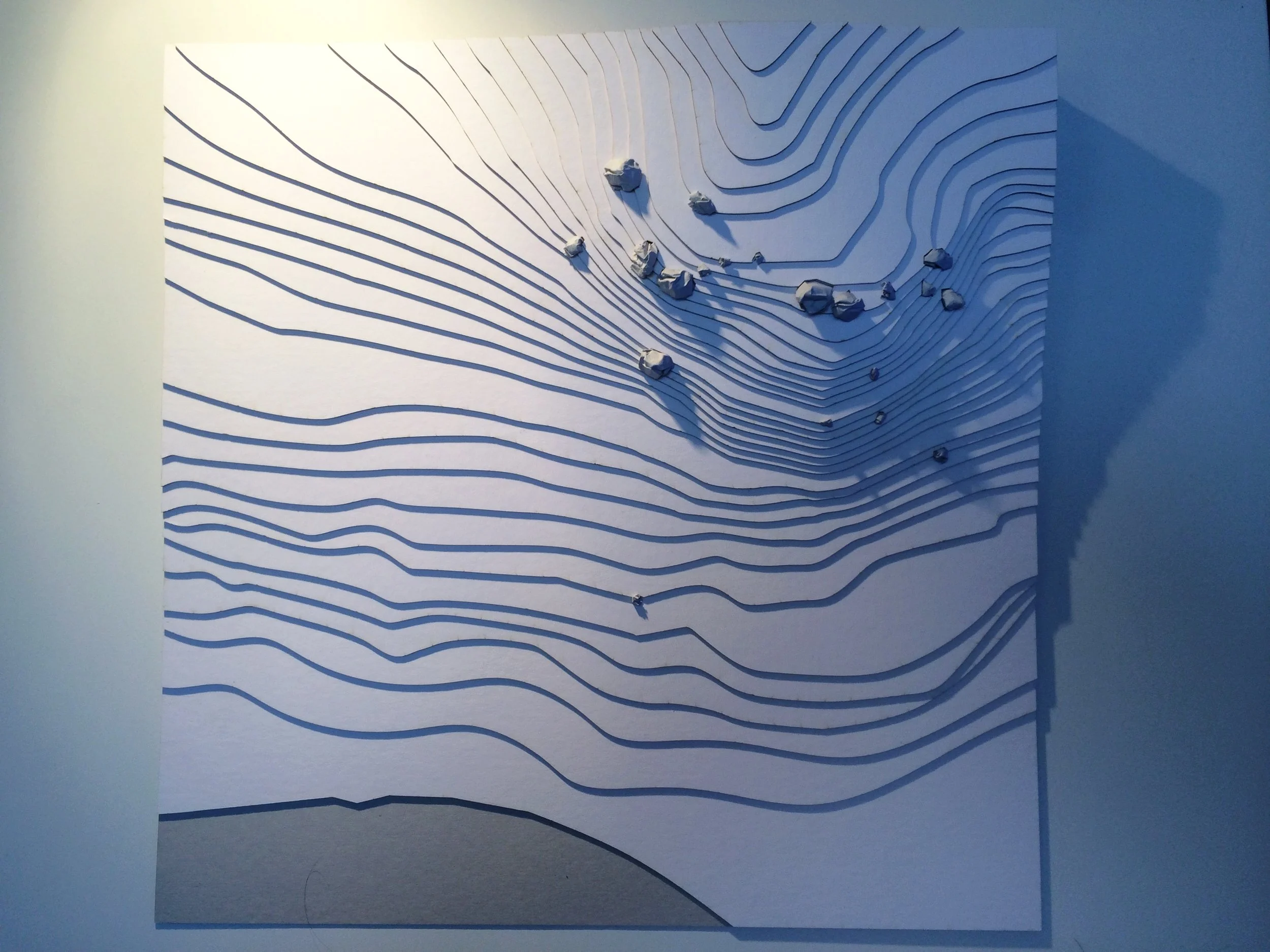

3axis CNC mill, 12"x12" self-laminated hardwood plate poster design

3axis CNC mill, 4"x4" self-lamined mixed-wood block

5axis CNC mill, 4"x4" self-laminted soft-wood pine block

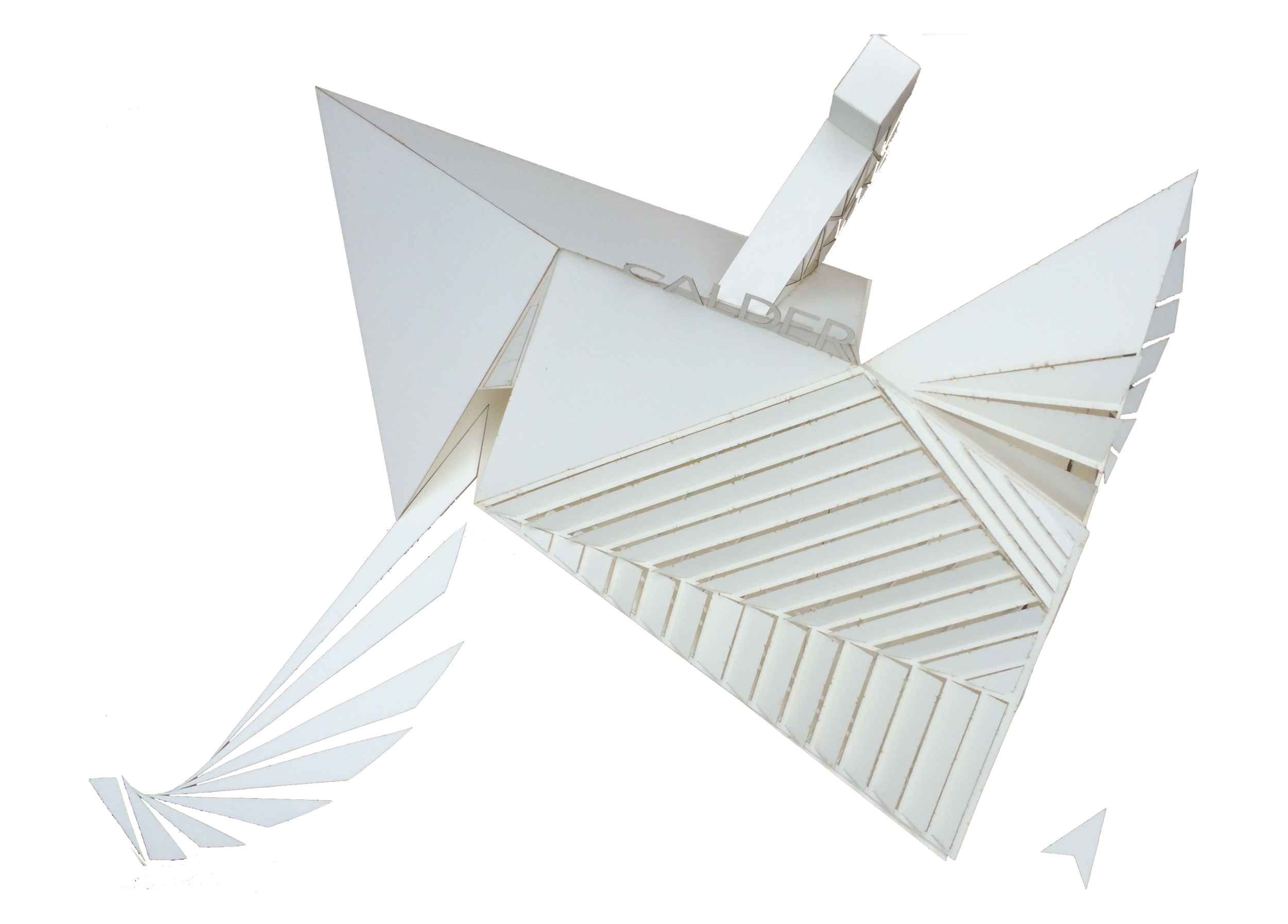

Lasercutting

Work between CAD files, Adobe Illustrator or AutoCAD files, Lasercutting software and a Lasercutter to model make for topographic, residential and mixed use commercial projects.